Osseointegration Machines

products

Bespoke Osseointegration Machines designed to enhance osseointegrated implant surfaces and success rates with advanced Contour Blasting technology.

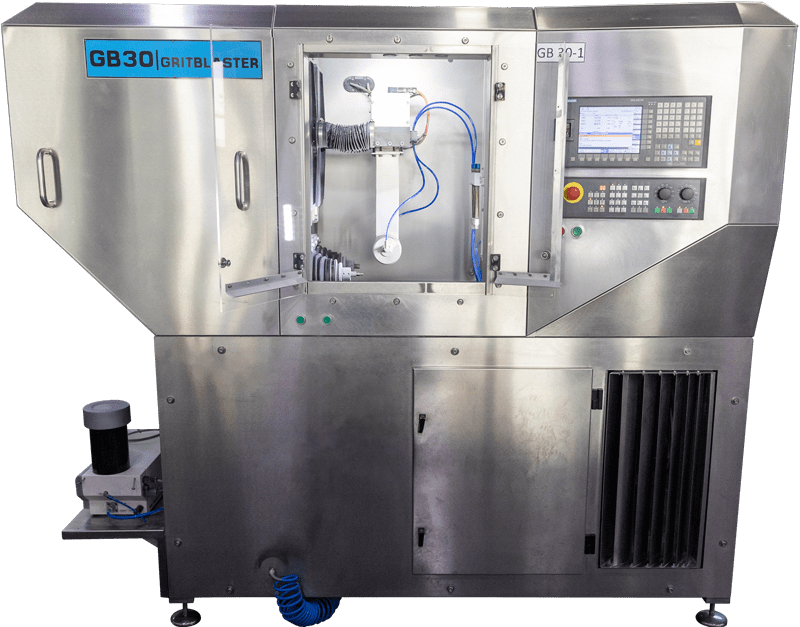

Countour blasting with the GB30 Gritblaster for Osseointegration

'Contour Blasting' is used to generate highly consistent and repeatable surfaces over complex implant geometry. Ensuring regularity of the surface topography across the entire device improves secondary fixation or coating adhesion.

When production demands vary, processing flexibility creates additional capacity and redundancy simultaneously. The GB30 is capable of processing component families with rapid changeover and setup times by modular fixturing and storing multiple blasting programs directly onto the control.

Meticulous design

The GB30 has been designed from the ground up as a workhorse for a high production, modern manufacturing environment. Meticulous design for reliability has led to the integration of high-quality mechanical components and robust Fanuc or Siemens CNC controls. A combination which has proven to be dependable over many years. Simple design and dedicated mechanical function are preferable to complex multi-axis articulating systems in harsh environments.

process efficiency

The cost of production is reduced by minimising the use of consumables. Blasting media and compressed air are spared by only blasting the areas required with optimal blasting parameters. Accuracy negates the need for manual masking processes. Low power consumption further improves sustainability.

enquire now

built for the operator

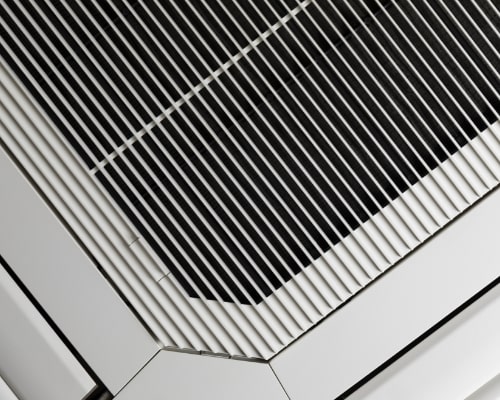

air filtration

A three-step air filtration system combining cyclone and pocket filters reduces dust exposure to the operator and captures used media.

ergonomic design

An ergonomic and familiar CNC control that is user-friendly and quick to program with familiar G-Code.

operator friendly

Operator fatigue is reduced as a result of LED lighting and a low noise backward swept centrifugal extractor fan.

gritblaster configuration

The base model of the GB30 offers a great platform for configuration to suit individual requirements.

CNC Control

Adopt either a Siemens or Fanuc CNC control (3+2 positional or 5 axis simultaneous). The Siemens 808D Advanced control comes as a standard. This allows for 3+2 axis articulation of the blasting nozzles relative to the component.

simultaneous processing

Dual-spindle configuration enables two items to be processed simultaneously. The quick change work piece system results in high productivity with minimal effort and rapid change-out times.

media types

Select blasting media types or specific third party external blasting unit integration. Multiple media types are accommodated with multiple nozzles. Y axis travel allows for off axis blasting as well as nozzle selection for an alternative media type.

control modes

The control can be configured in either ‘lathe’ or ‘milling’ mode, depending on the types of components being processed.

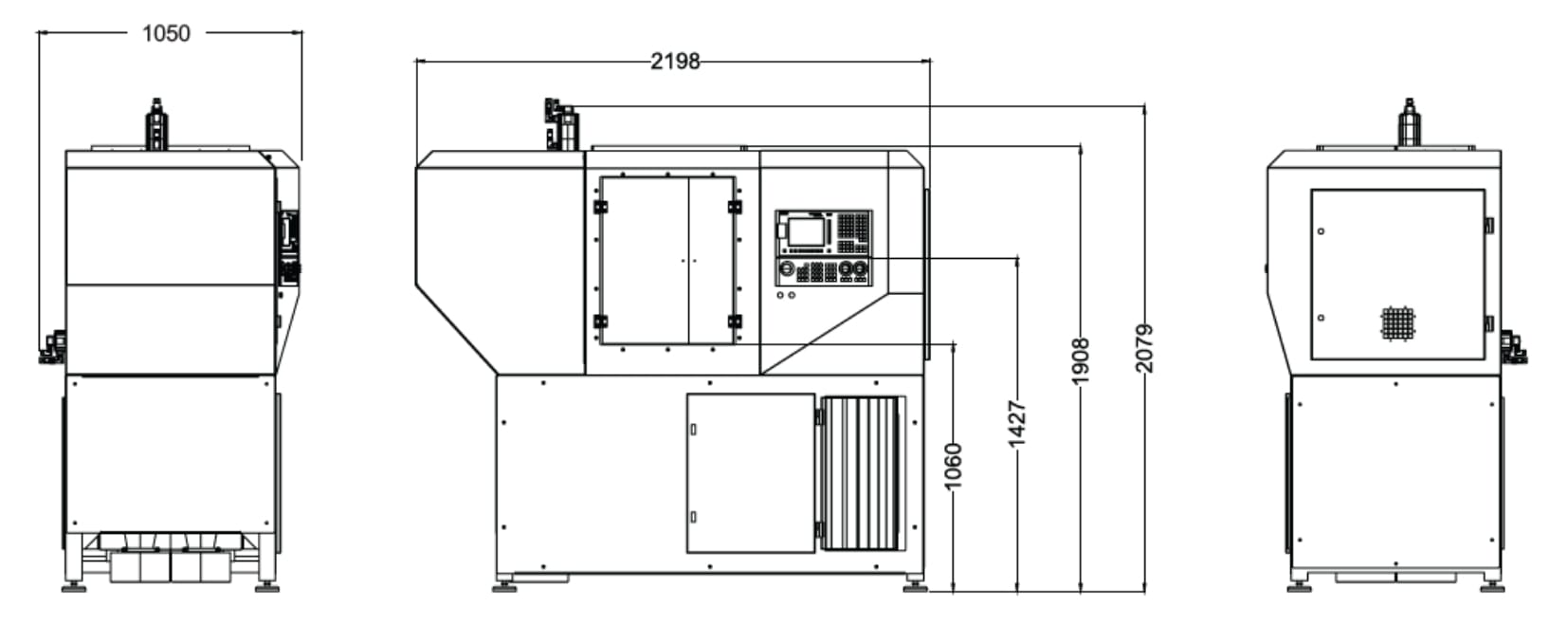

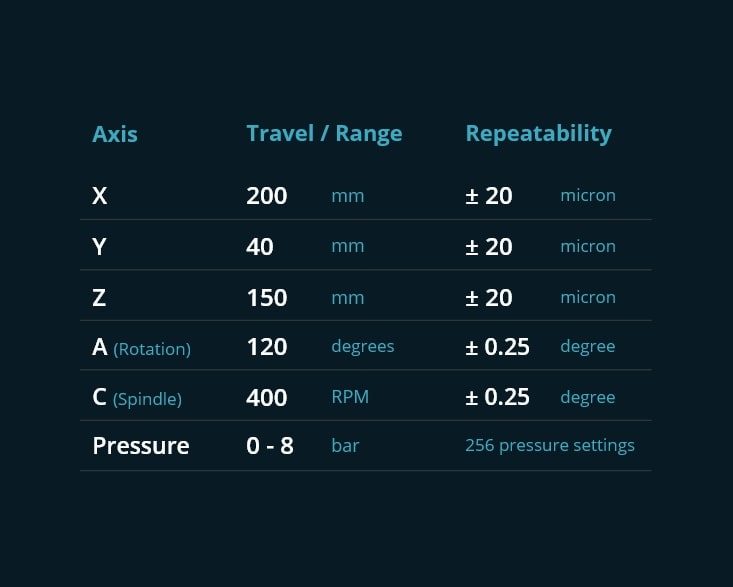

working envelope

Adapt the working envelope to cater for a range of components. The working envelope below is well suited to twin-spindle bone screw applications. Increased Y axis travel is available should a single spindle be more suitable.