applied science

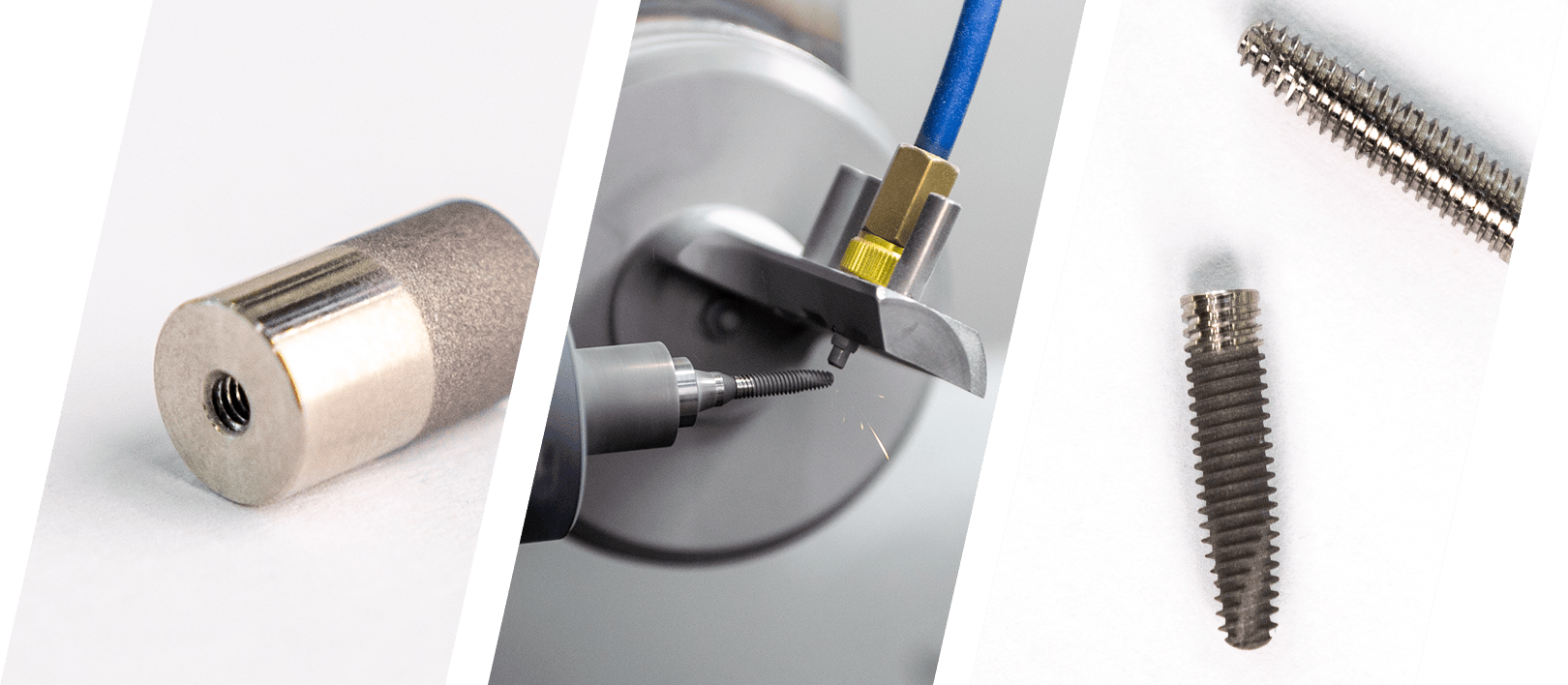

Leaders in osseointegrated surface enhancement

Applied Science designs and manufactures bespoke equipment for enhancing osseointegrated implant surfaces to greatly improve clinical success rates.

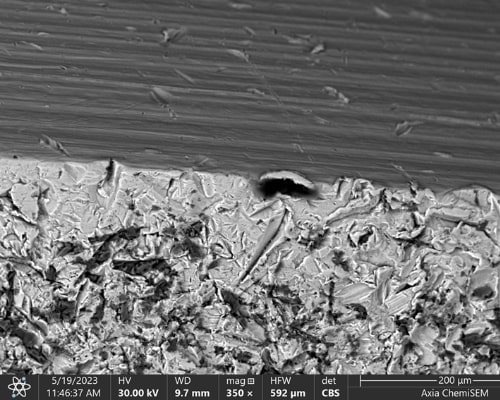

The key to stable osseointegration is a combination of biocompatibility and surface roughness

Applied Science designs and manufactures bespoke equipment for enhancing osseointegrated implant surfaces. Applications include the enhancement of titanium implants, which integrate directly with osteoblasts, as well as surface preparation for osseointegrating plasma sprays such as porous titanium or hydroxyapatite.

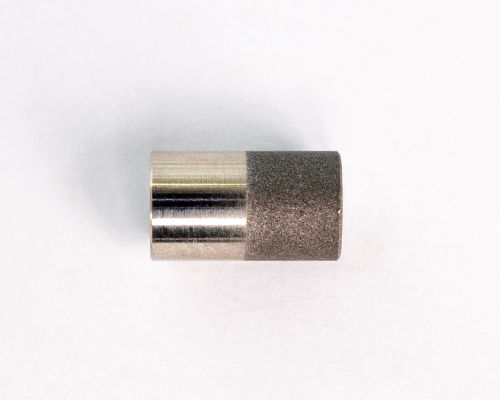

The key to stable osseointegration is a combination of biocompatibility and surface roughness. When an intermediary coating material is applied, the bond between this coating and the implant needs to be sufficiently durable over the lifespan of the device. Deploying Applied Science’s automated blasting machines assures quality and consistency of the roughening process. Partner with us to establish your ideal surface.

Superior process control

Blasting Accuracy

Targeted areas were improved without the use of masking materials or fixtures.

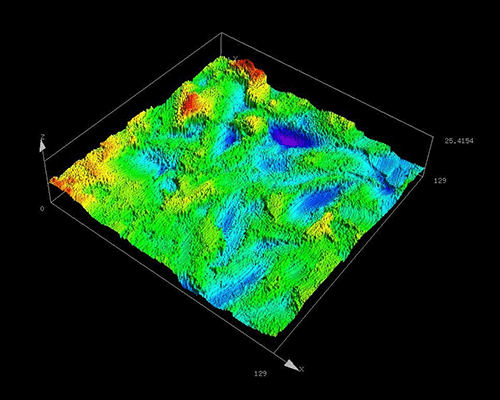

Uniformity of Surface

A roughness variation of just 0.3μm was achieved across different surface geometries.

meticulous research

Gain a competitive advantage by experimenting with different blasting parameters.

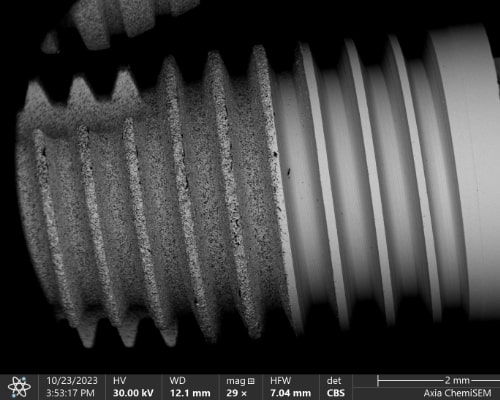

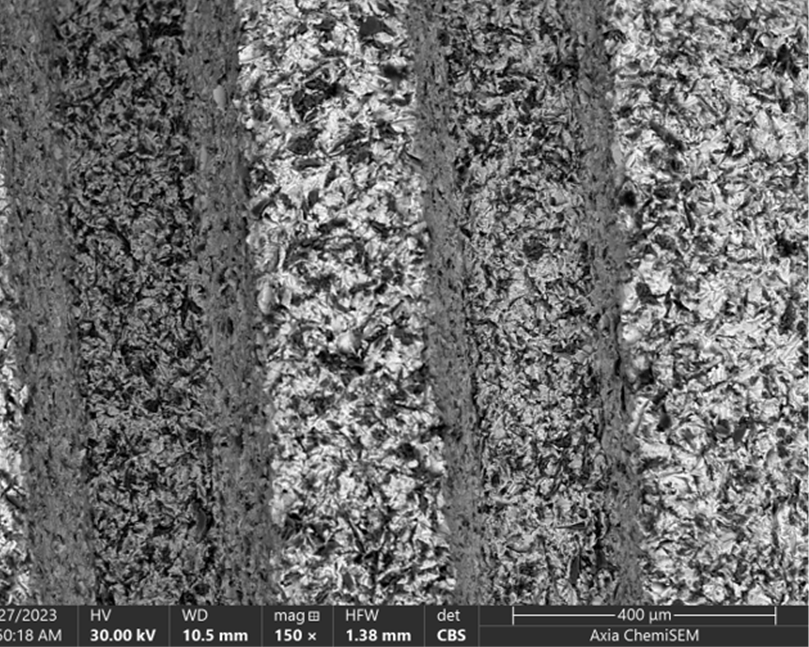

Magnification: 150x

Off-axis blasting minimises the occurrence of blasting particle inclusions.

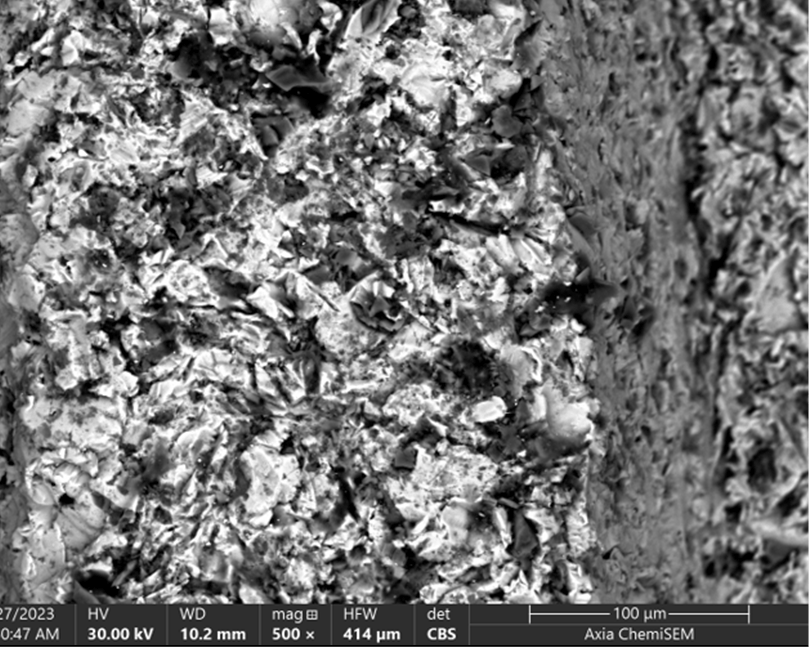

Magnification: 500x

Even under high magnification the surface roughness is homogenous.

The GB30 gritblaster

Meticulous design for reliability has led to the integration of high-quality mechanical components and robust Fanuc or Siemens CNC controls. A combination which has proven to be dependable over many years.

Simple design and dedicated mechanical function are preferable to complex multi-axis articulating systems in harsh environments.

surface enhancement applications

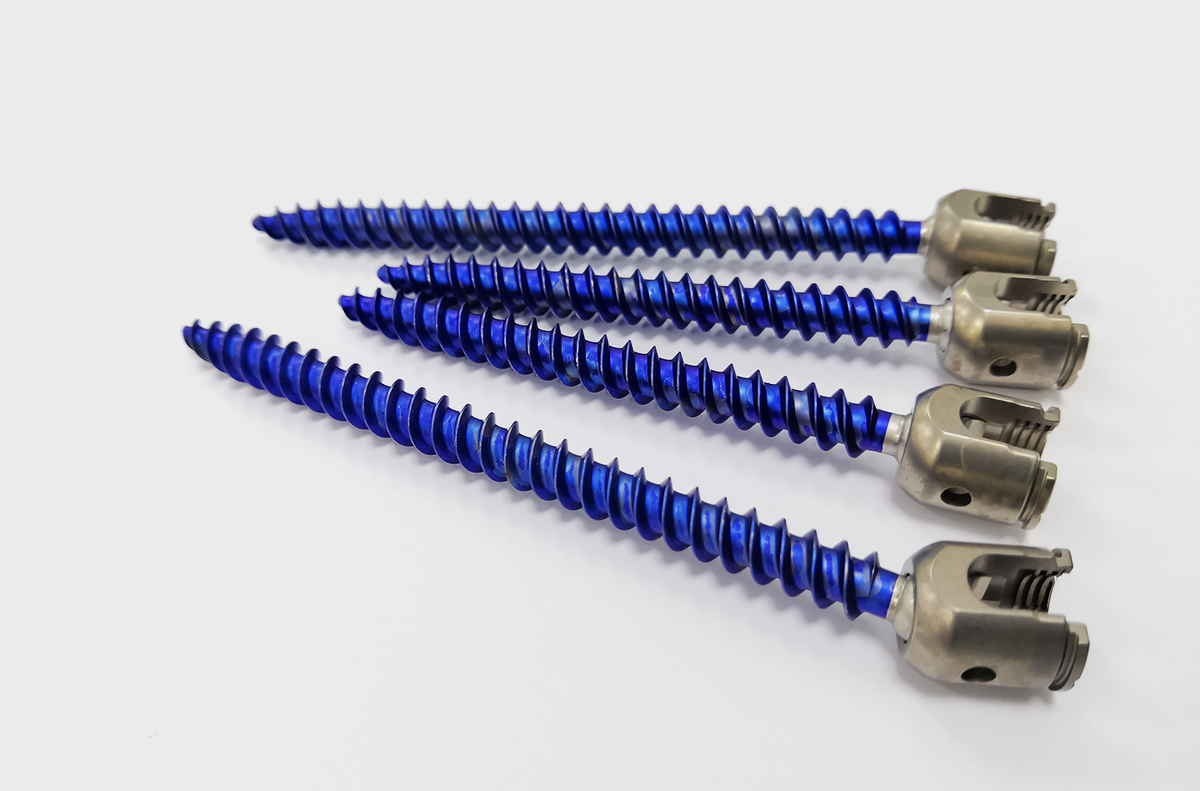

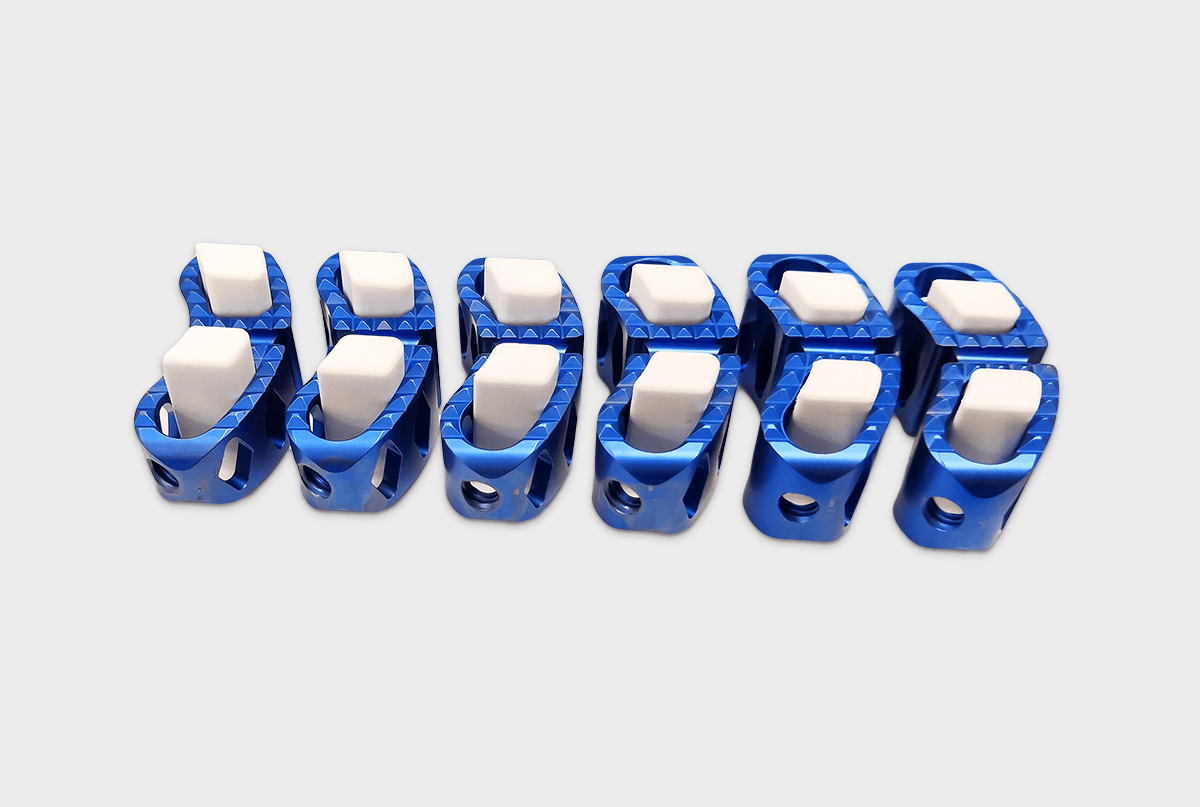

Osseointegration remains the gold standard for the long-term fixation of orthopedic implant devices.

This technique is used on various orthopaedic implants such as spinal and dental screws, and arthroplasty devices including knee, hip, and ankle replacements. Positive clinical results of these devices are dependent on consistent and predictable osseointegration.

Applied Science offers solutions to improve osseointegration strength or coating adhesion by roughening implant surfaces.

medical applications

dental implants

Spinal implants

Cage and instrumentation deburring

We invite you to visit us for a demonstration

"Excellent service"

Fast and Efficient Communication

"When I faced an issue, their response was immediate and solutions were provided with clear instructions. Their prompt and effective communication saved me a lot of time, and I truly appreciated their proactive approach."

about us

Applied Science was founded in 2018. Our journey began by deploying the first GB30 as a turnkey solution to a dental implant manufacturer. The success of the first unit resulted in further orders.

We strive to maintain our focus on quality and customer service. We have enabled these key objectives by vertically integrating our design and manufacturing under one roof. This approach allows us to provide turnkey solutions with streamlined project management, and rapid adaptability to the evolving needs of our clients.

Our team sets us apart and is the backbone of our success. Over the years, we have grown into a versatile group with a passion for engineering and a relentless pursuit of perfection.